During a discussion with a Komatsu representative, the customer raised an issue about excessive noise coming from the engine. As way of further investigation, Komatsu recommended the customer to undertake a sample test.

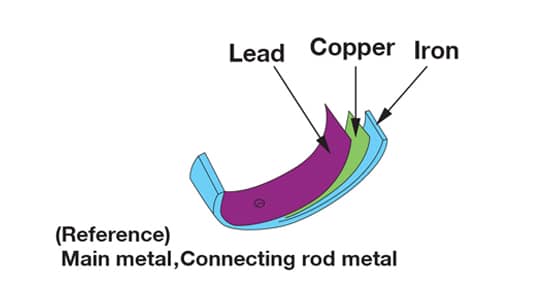

Using ICP analysis, Komatsu CMS was able to identify traces of copper, potassium and sodium – all signs pointing to coolant leak into the engine. In addition, tests recorded rising trends of lead, copper and iron, indicating bearing wear.

The oil sample was also submitted for a filtergram analysis which showed high iron levels, with small and large particles that were of a ferrous nature.

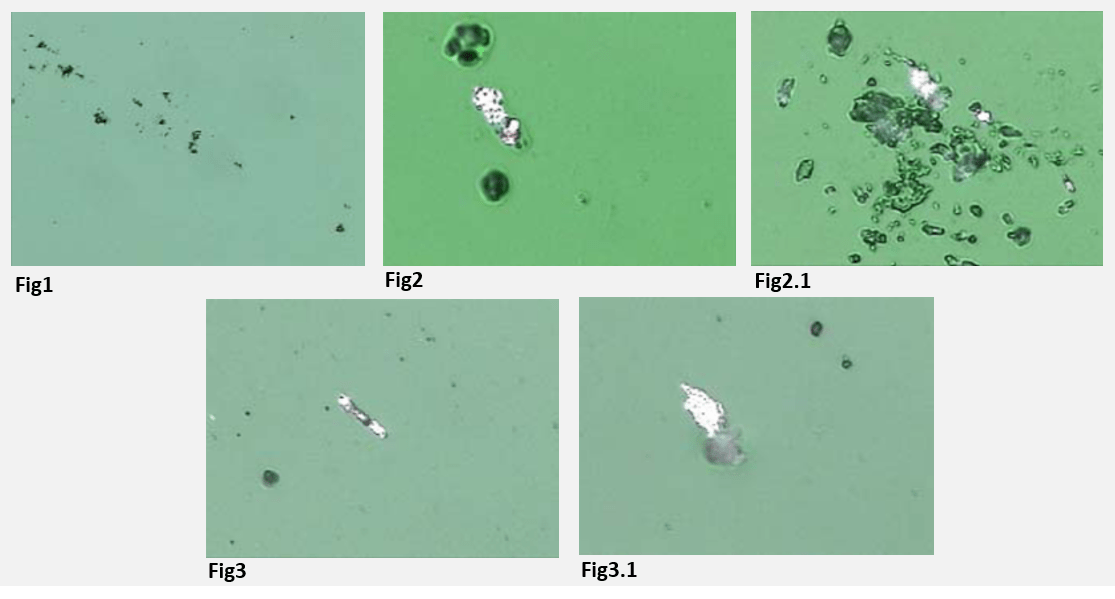

Fig1: This image indicates the average view at 100X of the magnetic and paramagnetic components of the sample after passing a diluted 1 CC portion of sample through the Ferrogram maker. The Ferrogram Maker's magnetic field arranges the sample magnetic and paramagnetic components into the typical rows as the sample runs down the glass slide.The microscopes bottom light shining up through the sample provides an indication as to the potential level of water debris and contaminating particles per cc.

Fig2 & Fig2.1: Metallic Fatigue Wear Particles

There was a few of this fine metallic wear debris caught on the Ferrogram Slide

Fig3 & Fig3.1: Metallic FatigueWear Particles

There was a few of this fine metallic wear debris caught on the Ferrogram Slide

Finding traces of these elements was a clear indication of bearing wear. Based on the amount of metals detected, it was crucial for the customer to investigate further. The important step was to ensure the machine was not being utilised to avoid any potential catastrophic failure and focus on replacing the damaged components in order to avoid any major costs related to an engine rebuild.

The customer has undertaken regular sampling their HM400’s engine oil with Komatsu over the years. The major benefit to the customer is the ability for Komatsu to measure the wear rate using trend-based analysis, a technique used to assess component life and predict the future wear rates based observed trend data.

The findings from the latest report provided Komatsu with the confidence in their findings which guided the customer to take the next steps in a timely manner.

At the completion of the detailed Condition Monitoring Services report, the Komatsu CMS analyst make direct contact with the customer. It is Komatsu’s duty to directly phone the customer when a machine is trending towards point of failure and in this case, there were no exceptions.

During the call, the customer then had advised that the machine was displaying a low oil pressure alarm, indicating that the traces of lead, iron and copper could be bearing wear.

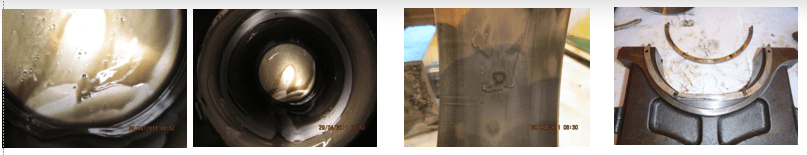

The next immediate action advised by Komatsu to the customer was to cut and inspect the oil filter, in which the customer found it to contain large ferrous and non-ferrous fragments. This visual information helped to confirm the bearing wear.

Advising that the bearing was wearing, the phone call quickly turned into a discussion about the next steps – having a Komatsu technician on-site. The Komatsu service supervisor got in contact with the customer to schedule a date that was suitable for the customer’s operations manager.

The Condition Monitoring Services report was then uploaded onto the customer’s account within my.komatsu.co.nz for ease of access.

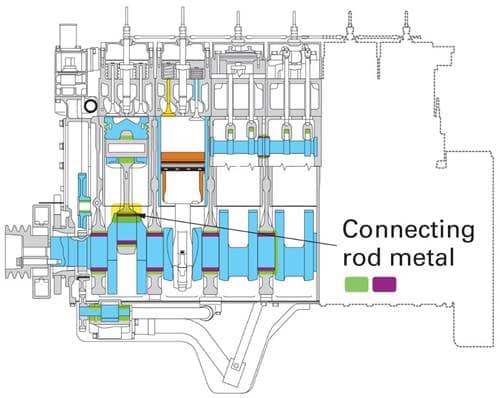

Upon inspection by our service technician, the engine’s main bearing was removed and found to contain cavitation (image 3). Further inspection revealed damage to the thrust bearings and the crankshaft using Komatsu genuine parts.

A Condition Report by conducted by the service technician at the completion of the job to ensure the machine could be utilised without issues.